DETROIT – As the COVID-19 pandemic spread across the country, it created a critical shortage of face masks. To help protect workers in essential services across the country, GM launched a rapid-response project to produce masks at scale on Friday, March 20. Seven days later, the team had produced their first sample on the new production line.

By next week, GM expects to deliver its first 20,000 masks to frontline workers.

Without help from GM’s partners around the globe, the project would have taken several months to plan and execute. The team working on GM’s face-mask project accomplished the task in just one week.

“Our team began looking at ways we could quickly utilize our talents and resources to help in the shared fight against COVID-19,” said Peter Thom, GM vice president, Global Manufacturing Engineering. “Working around the clock, our team rallied with incredible passion and focus to come up with a plan to produce masks that will help protect the women and men on the front lines of this crisis.”

Project kickoff to first mask in six days, 23 hours, 30 minutes

At 3 p.m. on Friday, March 20, the core team assembled for the first time, kicking off the project and starting the timer.

“Because we wanted to move fast, the team set an incredibly aggressive goal: To have the production line up and running tests within a week,” said Thom.

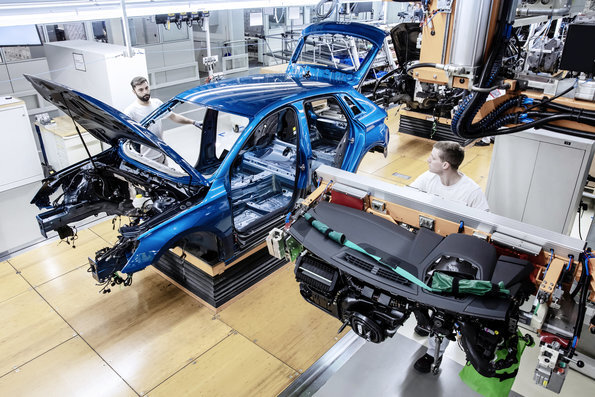

More than 30 engineers, designers, buyers and members of the manufacturing team were asked to help with product development, sourcing materials and equipment, and planning the production process.

“The first people we called were those who work with fabric vehicle components,” said Karsten Garbe, GM plant director, Global Pre-Production Operations. “In a few days, the company’s seat belt and interior trim experts became experts in manufacturing face masks.”

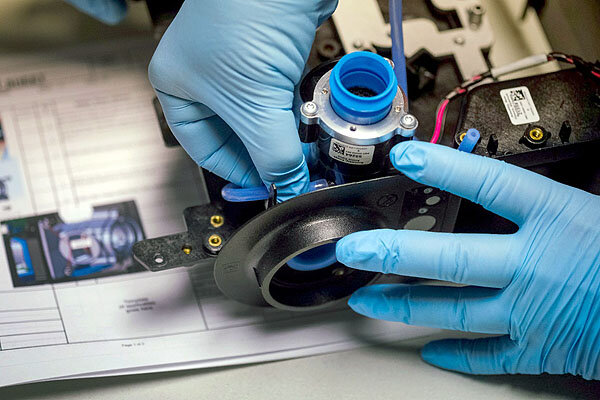

The team sourced the necessary raw materials by leveraging GM’s existing supply chain. These materials include metal nose pieces, elastic straps and blown, non-woven fabric filter material. Simultaneously, GM collaborated with JR Automation in Holland, Michigan and Esys Automation in Auburn Hills to design and build the custom machinery needed to assemble the masks.

For the project, the team selected the ISO Class 8-equivalent cleanroom at GM’s manufacturing plant in Warren. Work began at the Warren facility by removing existing equipment from the cleanroom. The team cleared approximately 31,000 square feet to accommodate the mask production lines. Crews then installed new electrical service lines to power the production equipment and assembly stations.

With the site cleared and prepped, production equipment and materials were then delivered to the Warren facility. Crews worked around the clock to install equipment and stage the production line. The team then tested each step in the production process, looking for opportunities to improve quality and production speed.

At 2:30 p.m. on Friday, March 27, the project team had their first production-made mask in their hands.

“Not only did the team make their goal, but they over-delivered,” said Thom. “They actually beat our deadline, running the first mask through the equipment 30 minutes ahead of target. We’re excited because this means we’re even closer to being able to protect the healthcare teams who are working tirelessly to save lives.”

20,000 masks expected to be delivered on April 8

The projected production volume is just as aggressive as the project’s timeline. By Monday, March 30, more than 2,000 masks were produced by teams working through the weekend. These initial test samples will be used to ensure the quality standards are met. Once these quality measures are completed, the team expects to start producing masks for delivery early next week.

GM and the UAW will seek more than two dozen paid volunteers from Detroit-area plants to staff mask operations. In addition, GM has implemented a series of safety measures to protect these team members through physical distancing, enhanced on-site cleaning and pre-entry health screening.

The team expects to have 20,000 masks ready for delivery on Wednesday, April 8. Once the line is running at full speed, it will be able to produce up to 50,000 masks every day – or up to 1.5 million masks a month. GM is currently developing a plan for distributing the masks, including using some of this important safety equipment to protect employees in critical GM operations.